How drone usage is resulting in better data, improved safety and reduced costs

The oil and gas industry holds immense potential for skilled UAS pilots with high end equipment. Oil and gas companies do not have skilled personnel to conduct these aerial inspection jobs. So, drone services are typically contracted out to drone service companies.

Reduced human intervention, accurate risk assessment and significant cost savings renders drones as the technology of choice for this industry. However, you need to be acutely aware of the high skill and huge capital requirement before you think of venturing into this field.

In this blog post, I consider the various ways in which drones can be used in the oil and gas industry. I also discuss some drone and cameras which are being used for oil and gas inspections. Do you need a fixed wing plane to conduct oil and gas inspections? Do you need a thermal camera? Or, would an EO camera suffice? Read on to find out.

Drone Applications in the Oil and Gas Industry

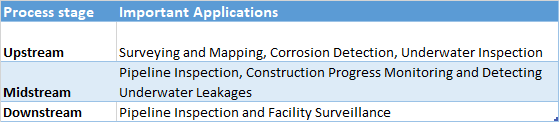

I have divided drone applications into 3 buckets: upstream, midstream and downstream. Please refer the below table:

Drone Applications in the Oil and Gas Industry

Drone Applications in the Oil and Gas Industry

“The Impact of Drones comes in the form of speed, risk mitigation and savings”

Drones have applications at every stage of oil and gas exploration. The first stage is surveying. Traditional surveying methods can often take too long. This can result in project delays and ballooning costs. You can collect accurate survey grade data at a much faster rate using drones. Hard to reach areas are easier to access. This can result in significant time and cost savings. Once construction commences, work progress can also be monitored with ease. The project manager can monitor progress in real time from the comfort of his site office.

Pipeline connections run for hundreds of miles between the oil rig and the refinery. Wear and tear resulting from hostile weather conditions or poor construction render regular inspections a must. Drones can be used to spot gas or oil leakages. Corrosion and heat spots can also be detected. This helps prevent leakages and hence, mitigate risk.

At the downstream stage, drones are being used to prevent a facility shut down. For instance, refineries burn off waste gas to produce more useful material. Inspecting such flame stacks is required by industrial regulations. Needless to say, this task is fraught with risk. By using drones, we can remove human intervention and also produce far more accurate data.

Drones and Cameras for the Oil and Gas industry

As I pointed our earlier, there are many potential applications of drones in the oil and gas industry. It is important to accurately assess your client requirements and your deliverable to zero in on the right equipment for the job. Let us discuss some options.

Because the DJI Matrice series offers greater flight time and larger payload capacity, it is being used by many catering to the oil and gas sector. You can also fly an EO camera and thermal camera at the same time, if required. You can fly the FLIR XT 640 camera which is compatible with Matrice 100, 200 and 600.Or, you might have to go really high end depending on your application.

Advantages of using a Fixed wing airplane for oil and gas

Advantages of using a Fixed wing airplane for oil and gas

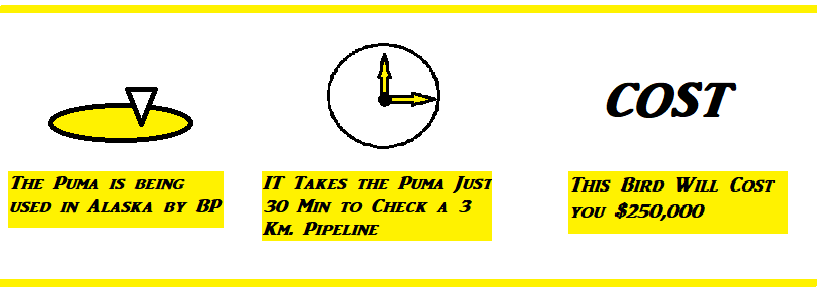

In 2014, BP became the first company to receive permission from the FAA to conduct commercial UAS operations over US land. This is for their Prudhoe Bay oilfield on Alaska’s North Slope. BP is flying the Puma AE UAV, a fixed wing airplane. Equipped with LiDAR, this fixed Twin airplane can check a 3 km pipeline in 30 minutes. Using traditional means would take 7 days to complete this same task.

The cost of Puma AE UAV? $250,000.

Recently the Silent Falcon was used to conduct oil and gas inspections in New Mexico. The purpose – visual inspection and detection of leaks. The falcon is a magnificent bird with a wingspan of 4.4 m and flying range of up to 15 km. And it is not cheap as well. This UAV comes with a hefty $250,000-$300,000 price tag.

Photogrammetry can be useful for monitoring construction progress. You can also detect spills and leakages using an EO camera. But if you wish to detect hot spots and other areas of potential risk, you will need a thermal camera. You can also detect leakages in underground pipes using a thermal camera. The surrounding area would heat up due to this leakage.

Conclusion

The oil and gas industry is a high margin, high industry. You need high grade equipment and a skilled organization to take up these jobs. If you are able to create these capabilities, the potential is immense. Sky-Futures, a company inspecting oil and gas rigs recently managed to raise $5.7 million from interested investors.

Do you have the financial and technical capabilities to venture into this field? Would you enjoy working in remote and lonely locations? Do you have a way of marketing your services to oil and gas companies? These are the questions that you need to ask yourself before you venture into this lucrative but complicated industry.

Check out our Medium page for more such content

Do not forget to subscribe and Listen to Ask Drone U, the #1 drone podcast

Connect with a vibrant drone community by becoming a Drone U member

Add Your Comment